Automotion Components Blanking Plugs

What is...

General Guidance

P0182

Hex head screw blanking plugs DIN 910

P0183

Hex socket screw blanking plugs DIN 908

P0184

Hex socket taper blanking plugs DIN 906

P0184.NPT

Hex socket blanking plugs NPT and NPTF dry seal

P0184.NL

Hex socket blanking plugs level seal

P0187

Hexagon blanking plugs DIN 7604 A

Threads

Blanking plugs come with either metric or inch threads. Most metric threads are fine threads (to DIN 13).

Inch threads come in four types:

- G indicates BSPP British Standard Pipe Parallel (to ISO 288)

- R indicates BSPT British Standard Pipe Taper (to ISO 7)

- NPT indicates National Standard Pipe Taper (to ANSI B1.20.1)

- NPTF indicates National Standard Pipe Taper fuel dry seal (to ANSI B.1.20.3)

- NL indicates National Standard Pipe Taper fuel level seal (to ANSI B1.20.3)

Materials

Blanking Plugs are available in three material types:

- Steel (untreated or zinc plated)

- Stainless steel (A2, AISI 303 and A4, AISI 316)

- Brass

Options: with built-in magnet or with NBR seal and O Ring.

Features

NPT and NPTF pipe threads

The two most common US standard taper pipe threads used are National Pipe Taper (NPT) and National Pipe Taper Fuel (NPTF). Applications range from electrical conduits and hand railings to high-pressure pipe lines that carry gass or caustic fluids. NPT threads are for mechanical or low-pressure air or fluid applications and often require the use of sealing compounds like Teflon tape, top provide the seal. When the application is more critical, and the sealing compound may fail due to high heat or pressure, NPTF Dryseal threads are used. This mechanical seal is produced by the mating and slight crushing of threads when a wrench is applied to tighten the fittings.

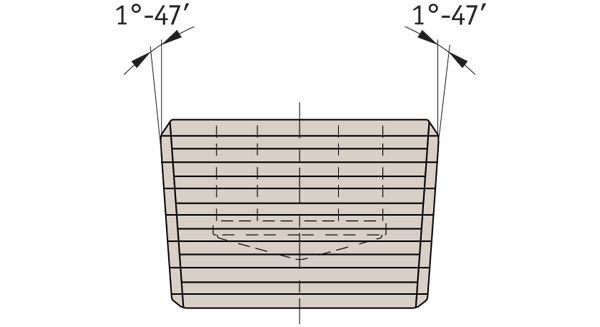

Visually, both threads appear to be identical. Both have a 1o 47' taper and a thread form with a 60o angle across the flanks of the thread. Both have the same pitch diameter at the top of the hole of internal threads or end of the pipe on external threads, and both have the same thread lengths or depths. However, there is subtle difference in the thread form that differentiates the two. The major and minor diameters of both threads differe slightly. With NPT threads, after tightening, slight spaces at the major and minor diameters maty exist that would allow the assembly to leak and therefore a sealing compound is often used to fill any gaps. On the other hand, NPTF threads are designed to ensure that sufficient crushing of the entire thread form will take place to produce a mechanical seal.

BSPT and BSPP pipe threads

The two most common British standard taper pipe threads used are British Standard Pip Thread (BSPT) and British Standard Parallel Pipe Thread (BSPP). BSPT is similar to NPT except for one important difference. The angle across the flanks of threads (if you sliced the fitting in half long-ways and measured the angle from root to crest to root) is 55o instead of 60o as it is for NPT. Thread sealant is needed to seal the male and female fitting together.

BSPP is most popular in the UK, Europe, Asia, Australia, New Zealand and South Africa. It is a parallel thread fitting that uses a bonded seal ring to do the sealing. This bonded ring seal is andwhiched in-between a shoulder on the male fitting and the face of the female fitting and is squeezed in place.

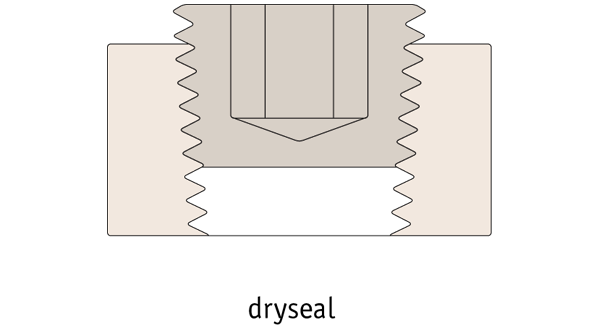

Dry seal and level seal plugs

A Dry Seal pressure plug is a plug that has a 1o 47' taper thread extending its entire length and is designed to have its threads mesh tightly with those of a tapered - threaded hole. The thread truncation is closely controlled at root and crest to ensure metal to metal contact at these points, coincident to or prior to flank contact. This prevents spiral leakage and provides more positive sealing. Dryseal NPTF pressure plugs can be used in NPT tapped holes, but for fullest protection against leakage they should be used in Dry Seal tapped holes that are taper reamed before tapping.

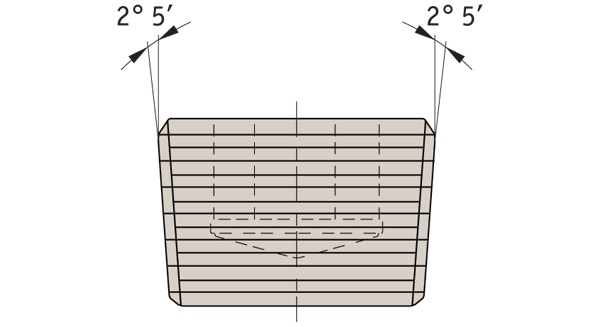

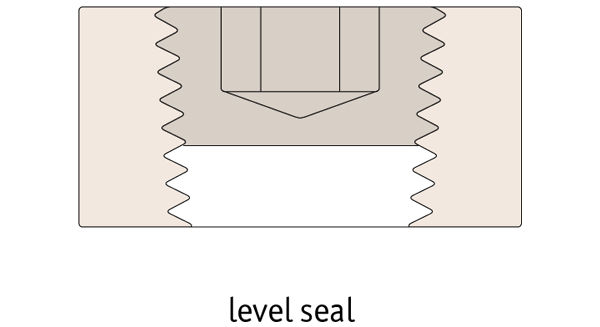

The Level Seal or Flush Type pressure plug is a plug having a 2o 5' taper thread extending it's entire length and designed to provide a flush condition with a standard 1o 47' tapered hole. It achieves a high pressure seal through the difference in taper, with dimensions pre-calculated to provide a higher sealing load near the large end of the plug and the threads near the top of the tapped hole. It is used in applications where high pressures are encountered and where protusion is undesirable.

The Dry Seal plug is longer than the Level Seal type and is most commonly used because it better fits holes that are not as accurately tapped.

The following diagrams show the main characteristics of both types of thread.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 00496138

Company VAT number GB 408154022