Lead Screws and Ball Screws | Automotion | Trapezoidal Lead Screws and Nuts | Rolled Ball Screws

Lead screw vs ball screw: what's the difference?

Lead screws and ball screws both translate rotational motion into linear motion, usually accompanied by linear guides that run alongside them.

They differ in their mechanism: lead screws can be more useful in "dirty" or otherwise corrosive environments that may affect the running of ball screws. In addition, they can be quieter and better in vertical running applications than ball screws. They are cheaper, and although usually thought of as less accurate than ball screws, we also stock some high precision lead screws which are manufactured to closer tolerances than standard lead screws.

Ball screws, unlike the simpler lead screws, operate by small, hard balls running through the channels of the screw shaft. These ball bearings are recirculated for continuous running and offer the main advantage of reducing friction and therefore maximising energy transfer efficiency. Due to this technology, ball screws are usually considerably more expensive than lead screws, although they may make up for this with a longer service lifetime.

Video demo: lead screw vs ball screw side-by-side comparison

This video is disabled because of your cookie settings.

As specialists in linear motion systems we offer you a choice of materials and sizes. So whether you need lightweight aluminium rails for use in aviation applications or stainless steel components for when exposure to water or corrosive chemicals is a factor, our knowledgable technical engineers are always on hand to provide assistance. If you require technical help or advice, please contact us.

Make sure you download a free Linear Motion Handbook here and utilise our free CAD to help you save time planning your projects.

For more of our lead screw products, visit our lead screws page - or, for more of our ball screw products, visit our ball screws page. Please also see our product videos on lead screws, where we compare and contrast ball screws with lead screws, and the relevant set-up options available for each system.

Lead screws from Automotion

Steel trapeziodal lead screws TR10 to 120. Right hand thread.

Steel trapeziodal lead screws TR10 to 120. Left hand thread.

Stainless steel trapezoidal lead screws (316 s/s). TR threads 10 to 70mm. Standard right hand threads.

Stainless steel trapezoidal lead screws (316 s/s). TR threads 10 to 70mm. Standard left hand threads.

Right hand thread. Rolled trapezoidal thread, stainless steel (AISI 304, A2) Manufactured to ISO 2901/209, DIN 103

Plain flanged bronze lead screw nuts - for trapezoidal threads.

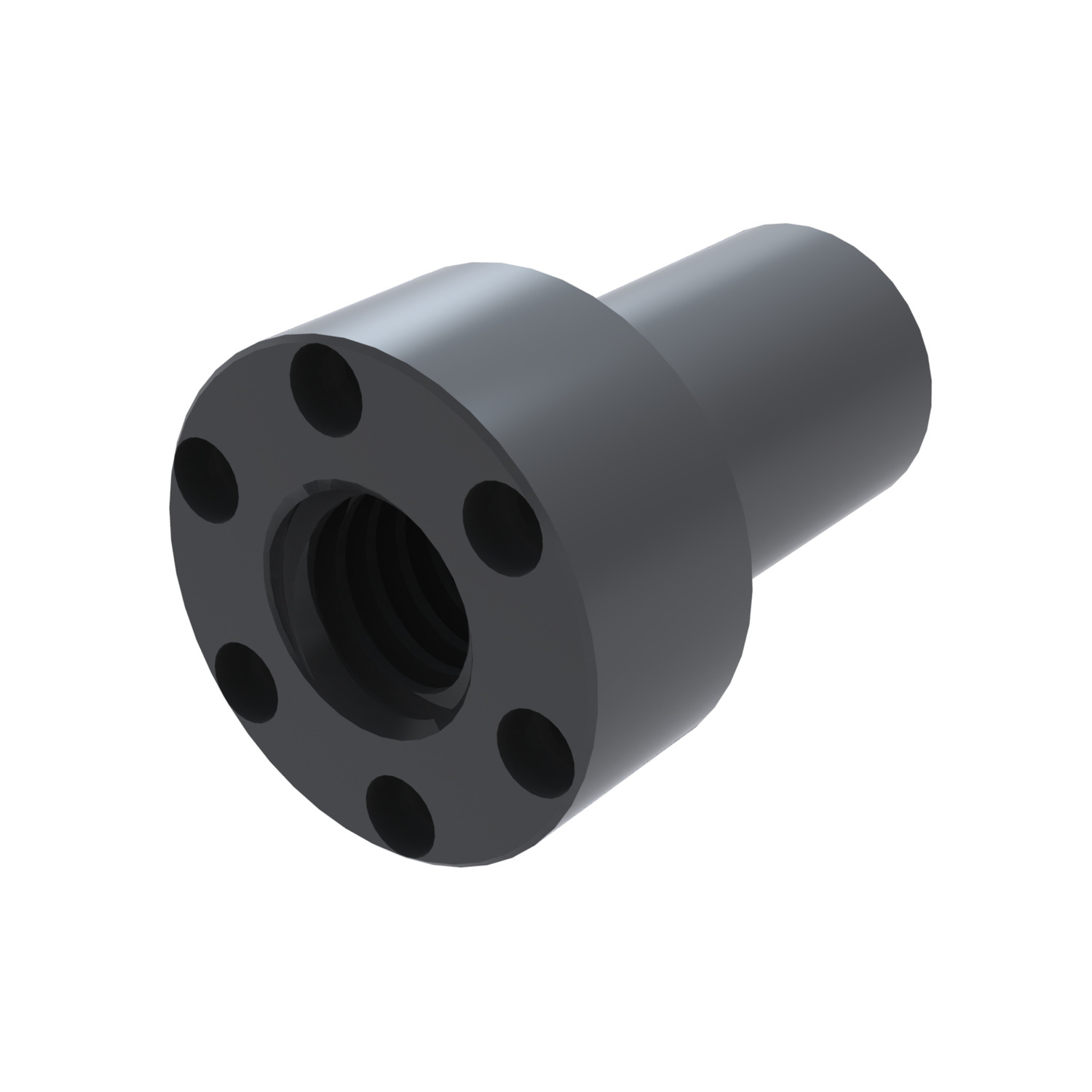

Flanged bronze lead screws nuts - for trapezoidal threads.

Cylindrical bronze lead screws nuts - for trapezoidal threads.

Square bronze lead screws nuts - for trapezoidal threads.

Steel cylindrical lead screws nuts - for trapezoidal threads.

Steel hexagonal lead screws nuts - for trapezoidal threads.

Steel square nuts for lead screws. Standard nuts are right hand thread, single starts.

Stainless steel lead screw nut for trapezoidal thread.

Self lubricating flanged nut for trapezoidal thread.

High precision lead screws with flanged nut. Stainless steel.

Ball screws from Automotion

Ball screws from 16 to 80mm diameter with a range of leads, normally supplied with flanged nuts or cylindrical nuts. We stock lengths of up to 3m but can cut to size/machine the screw ends on request.

Left hand ball screws and nuts are available from Automotion Components.

Black chrome-plated steel (CF53 or C55R), induction hardened to 60 HRC ±2, polished. Good resistance to corrosion and wear.

Miniature ball screws with small (6 to 14mm) diameter. Chrome plated steel for corrosion resistance - safe for use in food industry.

We stock a range of flanged ball nuts - the flanges are useful for attaching stages or other components to the ball screw system.

Bearing supports - compatible with both lead screws and ball screws

Floating rectangular support unit for lead screw.

Fixed support unit for the driven end of the lead screw.

Round support units for lead screws and ball screws also available.

See our full range of bearing supports here, including heavy load supports such as the one pictured (L1405).

Associated Products

Linear shafts and bearings for linear travel - see our linear shaft bars, support rails and bushings here.

Linear rails and carriages for reliable linear motion. See our full range of linear guideways here.

General Guidance

Compact Rail

Advantages

Easy to install. Allows for some misalignment at installation. Compact system, small footprint compared to other rail systems. Preload adjustable by hand.

Disadvantages

Although it can take very large loads it cannot take anywhere near as much load as the linear guideways rail system.

X Rail

Advantages

Cheaper alternative to the compact rail. Use of T and U rails allows for misalignment at installation. Preload adjustable by hand.

Available in AISI 316L stainless steel suitable for use in applications requiring a high level of corrosion resistance, including sea water.

Disadvantages

Cannot take as much load as other systems. Not suitable for moment loads.

Linear guideways

Advantages

Can take extremely high loads including moment loads. Very smooth in operation.

Disadvantages

Must be aligned very accurately which costs time and money preparing the mounting surface properly.

Shafts + bearings

Advantages

Available in a range of materials and sizes. A length of shaft bar is typically cheaper than the cost of an equivalent size precision linear rail.

Disadvantages

A larger diameter shaft would be required when there are long lengths and high loads involved compared with the size of an equivalent shaft support rail you would need. This is because they would only be supported at the ends and the shaft ends could bend in the middle if the diameter was too small.

Shaft support rail

Advantages

Shaft support rail systems have a shaft support along the full length so are less likely to flex.

Disadvantages

Similar to linear guideways, must be aligned very accurately otherwise any misalignment may cause the system to ‘snatch’.

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 2761902

Company VAT number GB 408154022