Lead Screws from Automotion

A lead screw is a screw which translates rotary motion into linear motion. Normally used as the driving mechanism in horizontal or vertically driven applications aided by linear guides for supports. They are described by diameter and pitch or lead. The pitch or lead is the amount of travel you get, or distance the nut travels along the screw for every complete revolution. They can be operated manually or motorised.

As specialists in linear motion systems we offer you a choice of materials and sizes. So whether you need lightweight aluminium rails for use in aviation applications or stainless steel components for when exposure to water or corrosive chemicals is a factor, our knowledgable technical engineers are always on hand to provide assistance.

Make sure you download your Linear Motion Handbook here and utilise our free CAD to help you save time planning your projects.

For applications that demand a high accuracy, we also stock high precision lead screws, which are made to closer tolerances than standard lead screw manufacturing allows. Click here to find out more now.

Lead Screw Options

Rolled trapezoidal C45 steel lead screws, right hand thread. Lengths of up to 6 meters can be provided. Tr 10 to Tr 120.

Rolled trapezoidal C45 steel lead screws, left hand thread. Lengths of up to 6 meters can be provided. Tr10 to Tr 120.

Rolled trapezoidal AISI 316 grade (A4) stainless lead screws, right hand thread. Surface hardness 280HB. Lengths of up to 6 meters can be provided. Tr 10 to Tr 120.

Rolled trapezoidal AISI 316 grade (A4) stainless steel lead screws, left hand thread. Lengths of up to 6 meters can be provided.

Right hand thread. Rolled trapezoidal thread, stainless steel (AISI 304, A2) Manufactured to ISO 2901/209, DIN 103

Cylindrical bronze lead screw nuts - for trapezoidal threads.

Square bronze lead screws nuts - for trapezoidal threads.

Steel cylindrical lead screw nuts - for trapezoidal threads.

Steel square nuts for lead screws. Standard nuts are right hand thread, single starts.

Stainless steel lead screw nut for trapezoidal thread. Stainless steel offers excellent corrosion resistance.

Square steel nut with holes for right handed thread screws. Useful for fixing additional elements onto the lead screw carriage (see lead screw video II below).

Manufactured to ISO 2901/2903 (DIN 103). Used for clamping and locking applications, and for slow rotational speeds with manual control; steel-to-steel contact surface is not suitable for motorised motion.

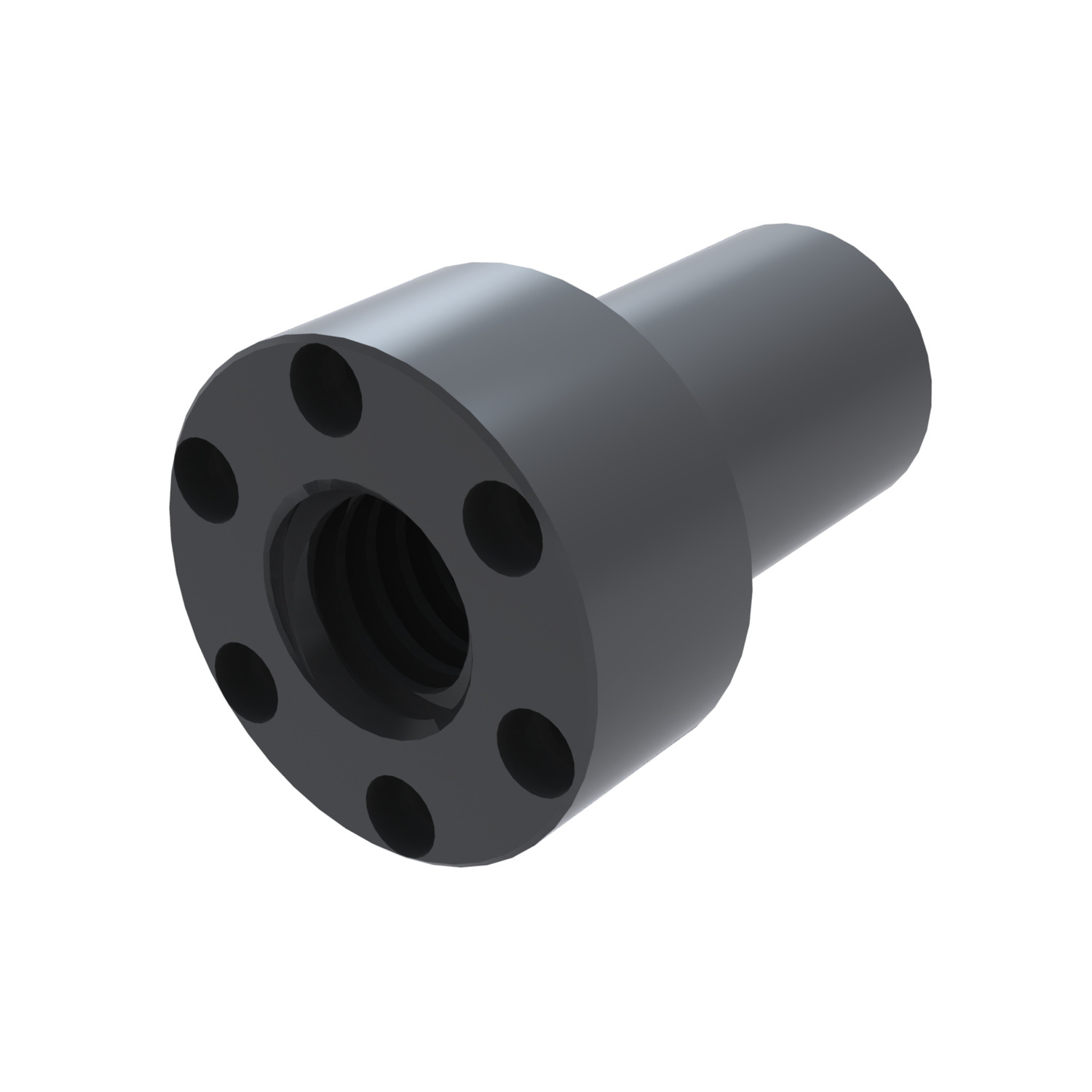

Plastic, flanged lead screw nuts with long thread to reduce wear and enhance service lifetime.

Can be used without lubrication for manual or powered control and medium/high speeds under moderate loads. Low noise.

Anodized aluminium or 416 stainless steel screw with round acetal resin nut. High precision. Nut fitted to screw to ensure anti-backlash.

Resin nut (PPS), to suit lead screw L1349. High precision. Tight axial clearance.

Stainless SUS 304, high helix lead screw. High precision. See L1350 for corresponding nut.

Steel with black oxide finish. Nickel plated versions for cleanroom applications can be produced on request.

Floating round support for lead screw. For more information on support units, including example applications and lead screw end machining, see the end of this catalogue section. Note that we can perform the lead screw machining for you if requested.

These fixed support units are for the driven end of the lead screw. This unit can easily be bolted down.

Floating support unit for the non-driven end of the lead screw. Bearings are sealed and lubricated for life.

Fixed support unit for the driven end of the lead screw. Please note that we can machine the ends of your lead screw to your requirements.

Floating support unit for the non-driven end of the lead screw. Having one fixed and one floating support unit means your lead screw will not seize up.

We also stock a range of other lead screw accesories, such as handwheels for manually driven lead screws.

Lead Screw Machining

We can perform lead screw end machining to support your applications. Please submit your technical drawings to our technical sales team, who will be able to help.

Contact our sales teamAssociated Products

Linear guideways, which can run alongside lead screws, can support very high loads and provide smooth linear motion. For more information, see our linear guideways page.

Ball screws are a higher cost alternative to lead screws. They can provide smooth and reliable running over long service lifetimes, because the ball bushings in the nut help to lower friction during service. To see more ball screw products, visit this page.

Product Videos

I: Introduction to lead screws

This video is disabled because of your cookie settings.

II: Application and setup of lead screws

This video is disabled because of your cookie settings.

III: Selection of guides and lead screws

This video is disabled because of your cookie settings.

Product Selection

The choice between different types of lead screws and lead screw nuts available is generally made after taking into account the following factors.

Choice of lead screw

Working environment

For work environments where there are no particular corrosive or oxidising agents our steel (L1320 and L1321) lead screws can be used.

Where these conditions are not met, we recommend using our stainless steel screws (L1322 and L1323) which are particularly suitable in the following cases:

- With a relative humidity of 70-80% and above.

- Immersed in water (including sea water).

- In the presence of particular corrosive agents such as chlorides. In case of highly corrosive agents please contact our Technical Department.

- In the food industry or pharmaceutical industry, where they are used with stainless steel or bronze nuts.

- Where the lead screws cannot be reached for lubrication. In particular, for lubricating “maintenance free” fi ttings they are coupled with plastic nuts.

- Where working temperatures are relatively high (above 200°C) - because stainless steel has a structure that is more suited to higher temperatures.

Backdrive

Irreversibility defi nes how much the nut can “backdrive” down the lead screw. If a nut cannot backdrive down the screw then it is irreversible. This is especially important if the lead screw and nut are being used in a vertical application i.e. in this situation no backdrive is normally acceptable.

Lead screws with a lead angle of <2° 30’ are completely irreversible i.e., they cannot backdrive. Lead screws with a lead angle >5° but <6° still have a good degree of irreversibility and may in some instances exhibit some backdrive.

Lead screws with a lead angle >6° have zero irreversibility, therefore the nut may backdrive down the lead screw with little or no load applied.

This is important to know in vertical applications.

Choice of lead screw nut

Working environment

Our bronze and stainless steel 303 lead screw nuts, are resistant to standard oxidizing agents that occur in various applications.

Where corrosive agents are present, please contact our Technical Department for advice.

In applications where the presence of added lubricant (grease or oil) is not allowed we recommend the use of self-lubricating plastic nuts.

The use of plastics can however be limited by the specific working conditions, therefore please consult our Technical Department should you wish. This is because plastics have excellent self-lubrication features, but at the same time have restrictions on the working temperature or moisture absorption problems, (as well as some mechanical properties that may not be suitable for the intended use).

Single start or double start

Pitch

The axial distance between threads. Pitch is equal to the lead in a single start screw.

Lead

The axial distance the nut advances in one revolution of the screw. The lead is equal to the pitch times the number of starts.

Lead = Pitch x No. of starts

For example: A 10mm diameter lead screw has a pitch of 2mm. On a single start lead screw the lead is also 2mm. On a twin start lead screw the lead is 4mm

Screw starts

The number of independent threads on the screw shaft, example one or two.

Lead Screw Technical Specs

Lead Screw General Guidance

General Guidance

Compact Rail

Advantages

Easy to install. Allows for some misalignment at installation. Compact system, small footprint compared to other rail systems. Preload adjustable by hand.

Disadvantages

Although it can take very large loads it cannot take anywhere near as much load as the linear guideways rail system.

X Rail

Advantages

Cheaper alternative to the compact rail. Use of T and U rails allows for misalignment at installation. Preload adjustable by hand.

Available in AISI 316L stainless steel suitable for use in applications requiring a high level of corrosion resistance, including sea water.

Disadvantages

Cannot take as much load as other systems. Not suitable for moment loads.

Linear guideways

Advantages

Can take extremely high loads including moment loads. Very smooth in operation.

Disadvantages

Must be aligned very accurately which costs time and money preparing the mounting surface properly.

Shafts + bearings

Advantages

Available in a range of materials and sizes. A length of shaft bar is typically cheaper than the cost of an equivalent size precision linear rail.

Disadvantages

A larger diameter shaft would be required when there are long lengths and high loads involved compared with the size of an equivalent shaft support rail you would need. This is because they would only be supported at the ends and the shaft ends could bend in the middle if the diameter was too small.

Shaft support rail

Advantages

Shaft support rail systems have a shaft support along the full length so are less likely to flex.

Disadvantages

Similar to linear guideways, must be aligned very accurately otherwise any misalignment may cause the system to ‘snatch’.

FAQs

What are Lead Screws used for?

Lead screws are commonly used as part of a linear motion control system, facilitating the transformation of rotary or turning movements into linear movements. Used for either vertical or horizontal movements, lead screws are ideally suited to many applications including heavy lifting applications.

How do Lead Screws work?

Lead screws typically work in one of two ways: either the shaft rotates and transfers power to the nut or the shaft is stationary and power is applied to the nut. In the first instance the nut's rotational movement is restricted whilst the shaft rotates causing the nut to move along in a linear motion. In the second instance, a motor or manual force is applied rotating the nut and pushing it along the shaft's axis.

Lead Screws vs Ball Screws: What's the difference?

On a basic level the difference between lead screws and ball screws is that ball screws utilize ball bearings to remove friction between the nut and screw, lead screws do not. Another key difference is that ball screws are typicall available with greater pitches which when combined with the ball bearings, mean they can be run at greater speeds. Generally speaking, if you have an application requiring high accuracy and/or high speeds then choose a ball screw. In most other applications a lead screw will be sufficient and are more cost effective. For more guidance about the best product for your application please get in touch.

Email Newsletter

Be the first to receive the latest news and exclusive offers via our newsletter.

Alexia House, Glenmore Business Park

PO19 7BJ Chichester

United Kingdom

0333 207 4498

sales@automotioncomponents.co.uk

Route via Google Maps

Company registration no: 2761902

Company VAT number GB 408154022